PURE FIRECLAY FARMHOUSE SINK PRODUCTION

Fossil Blu fireclay farmhouse sinks feature authentic SOLID fine and ultra-fine fireclay. Authentic fireclay is a semi-rare natural white clay containing higher concentrations of fine-grained quartz (silica) than typical ceramic (kaolin) clays. When the silica-based glaze is applied (learn more about our glaze below) and then fired at extremely high temperatures, the silica of both the quartz and glaze fuse together, creating a single structure. This “single structure” is what separates fireclay from typical/inexpensive ceramic products, which are fired at lower temperatures, exhibit little fusing, and are thin and/or hollow structures. This is also why genuine fireclay sinks, such as Fossil Blu, are more expensive than inauthentic “fireclay” sinks found in the marketplace.

We source our fireclay base material from mines following reduced-input/output (more sustainable) mining practices across Europe and Asia.

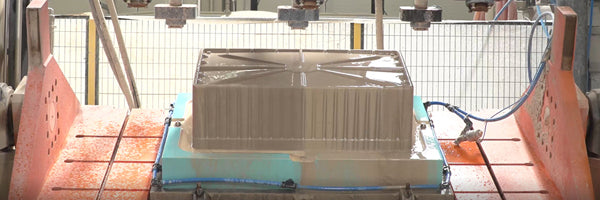

Once at our factory, the clay is mixed with just water, then compression molded via a 50,000-pound hydraulic press. This high-pressure process not only forms the sink, but removes any trapped air, resulting in a solid structure that will not bubble during kilning. The sink is then low-fired (mild heat) for two days to dry before heading to the glazing room for finishing.

Fossil Blu’s legendary silica-based glaze is robotically applied, allowing for up to twice the glaze thickness compared to hand-sprayed glazing techniques.

Fired (kilned) at over 2200-degrees Fahrenheit, the glaze fuses with the fireclay substrate during kilning to create a permanent, enameled, single-structure.

Fossil Blu Fireclay Sinks

Authentic creations for the discerning homeowner.